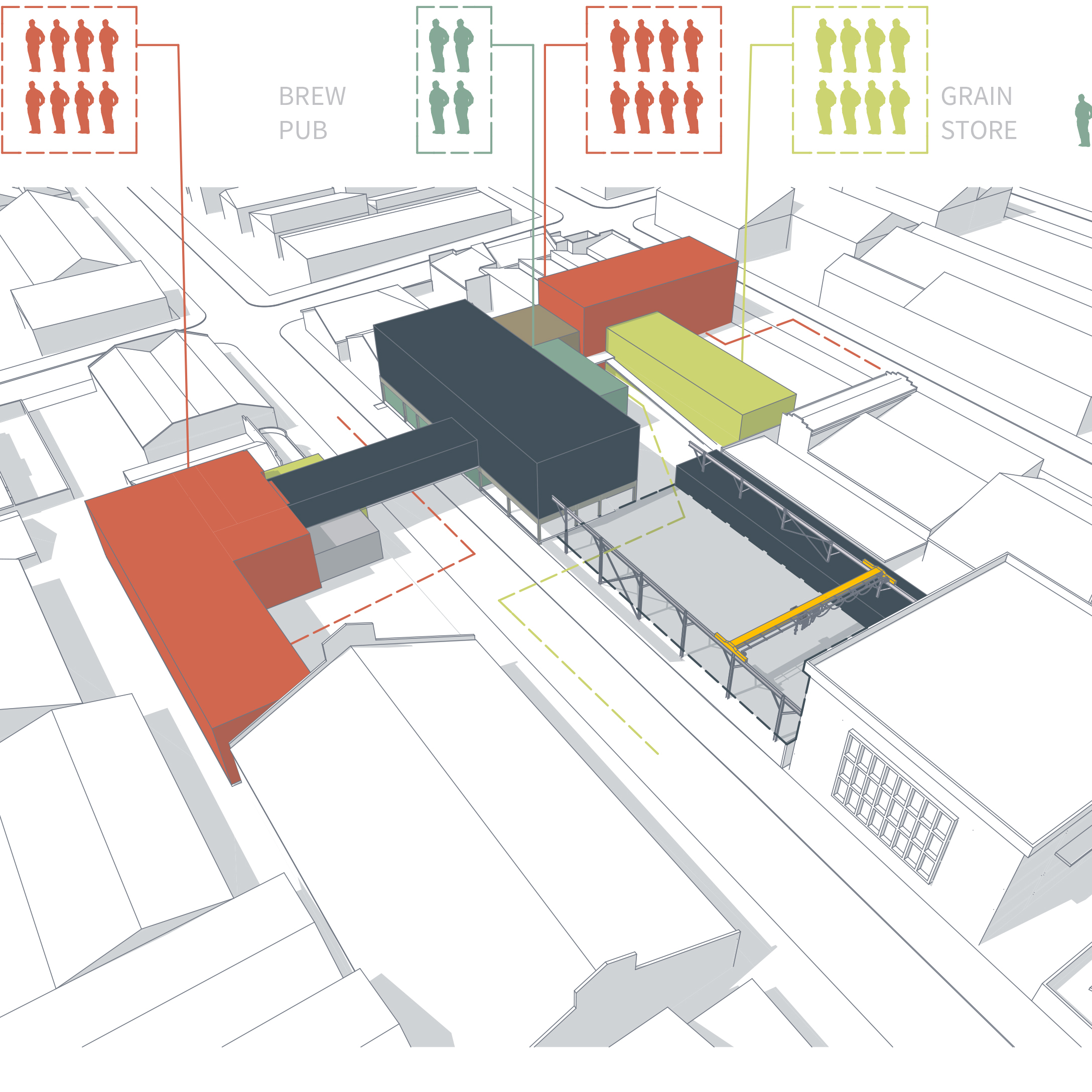

2015 thesis project

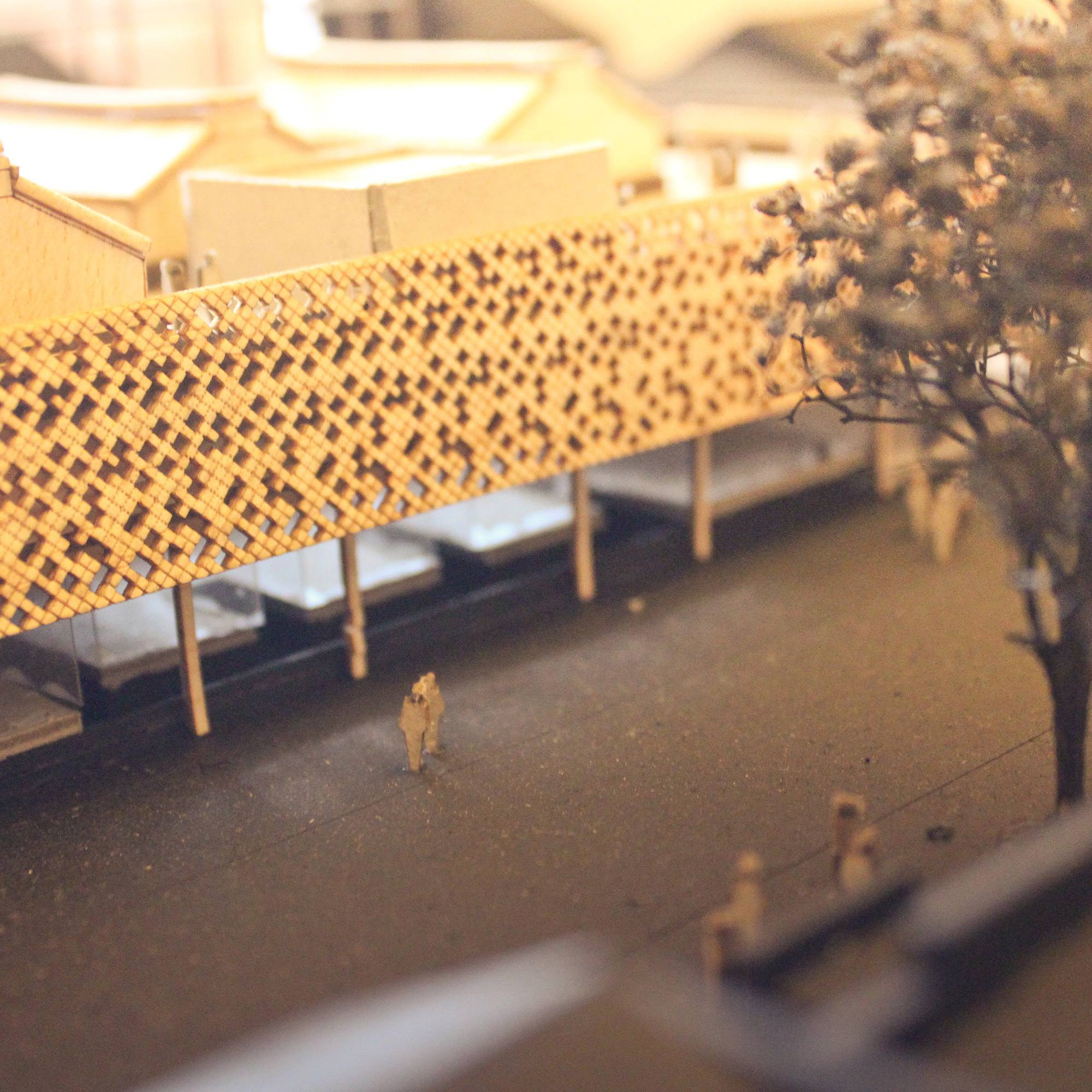

The brewery’s northern facade is an important public face for the building. Here the restaurant and co-operative breweries face on to Fourth Street, the scheme’s main pedestrian interface, and the road which carries finished products away from the facility. The glazed facade is shielded by a steel gridded screen supported by a galvanised structure which carries a narrow walkway from where the facade can be maintained. This narrow corridor will also provide a break-out space from the restaurant for smokers or people looking for some fresh air, and is designed to be just wide enough for a person to pass someone leaning against the balustrade.

The screen is composed of a grid of 200mm cube pockets into which special blocks can be placed dependant on the shading requirements at different times of the year. This will be a living facade, changing over time, a shifting pattern of open and closed points. The blocks are similar to traditional clay bricks, but with the addition of brewers’ spent grain (BSG), a natural by-product of the brewing process which is typically sold off as animal feed. The use of BSG in building materials is an area of considerable contemporary research. An article by The New Scientist reports on a study in which a mixture containing five percent spent grain was fired to produce a brick with the same strength as a normal brick, but which accounted for a 28% decrease in heat transfer. It is intended that an ongoing working relationship be established with a local brick manufacturer to produce the bricks.

I wrote a script in Grasshopper to define the screen wall parametrically, so that I could adjust the number of blocks in the wall depending of the amount of solar shading cover needed at different times of the year. I started by defining the overall dimensions of the screen, and the size of each individual block. (1) I then divided the surface of the screen up into a grid of block-sized divisions using a Lunchbox diamond-grid definition. (2) The grid also needed to account for the frame in which the blocks were to sit, and so a few more calculations were needed to set up the steel elements. (3) At this point the definition breaks into two parts – one each for the bricks and frame. (4) The most important part of the script was the definition which was to randomly populate the frame with bricks. I had to find a way of parametrically adjusting how many blocks were placed in the corresponding slots in the steel frame. First, I defined the basic block form, constructed on the centre points of the grid, so as to fill the whole frame. (5) I then listed all of the points and performed an operation with some extra calculations to randomly remove list items. (6)

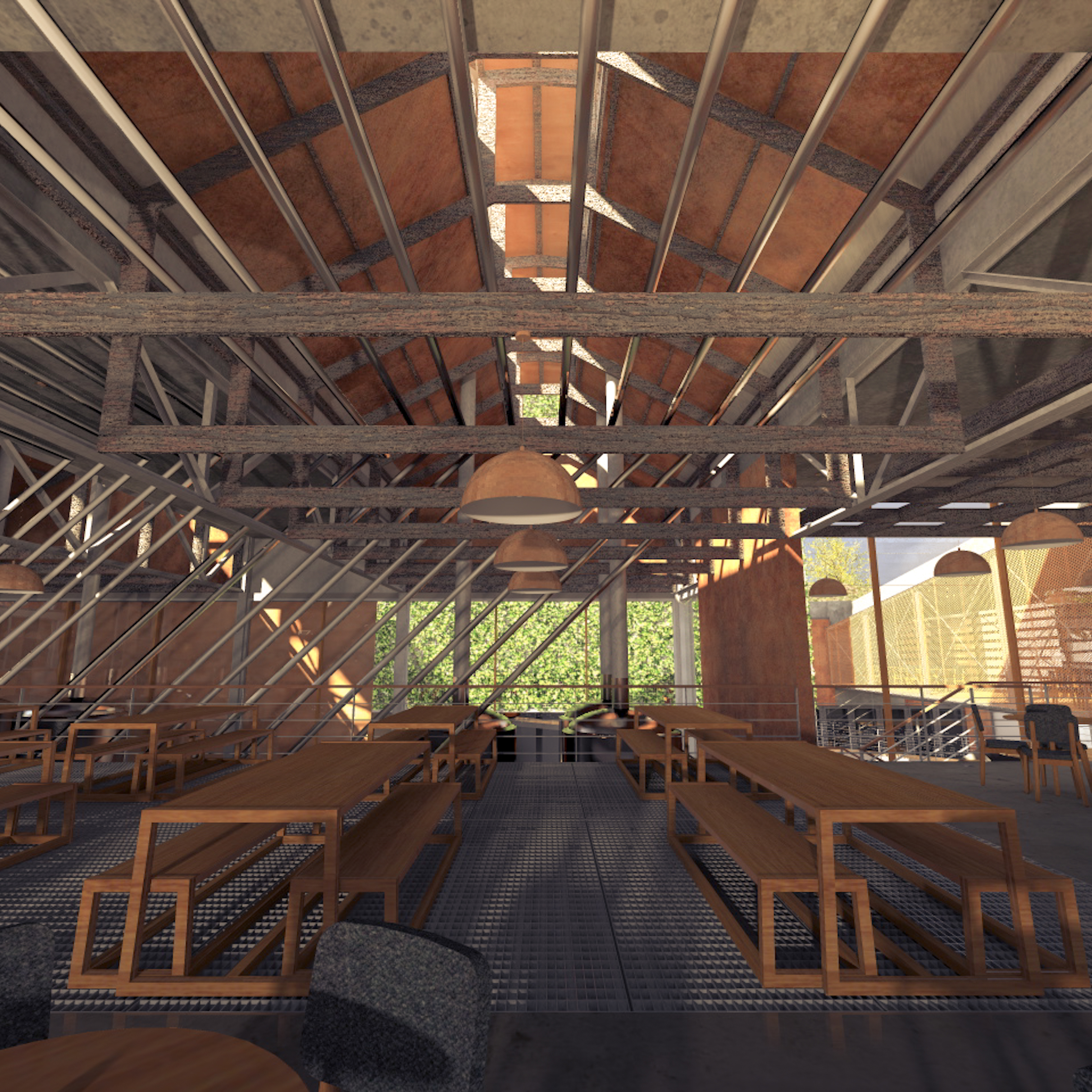

The northern screen wall, and west facade are key parts of a system for naturally heating and cooling the building. During the brewing process, beer must be heated and cooled rapidly at different stages of the brew. Since the building

also needs to be heated and cooled to create comfortable spaces, I have designed a system in which stainless steel pipes (for beer sterility) are run throughout the building, carrying either hot or cold liquid. A series of valves (1) is used to

send the beer where it is needed. During winter, hot beer is cooled by cold wind and cool spaces are heated as a result, and during summer, cold water is warmed by the sun, (2) whilst hot spaces are cooled by the breeze blowing over cold pipes. I had initially intended treating mine run-off water from the area, and using this to brew with, but after consulting an expert from the University of the Witwatersrand Industrial and Mining Water Research Unit, who told me that, “By using tap water, you are essentially using treated mine water,” and that there was so benefit to doing otherwise, I conceded to drawing all of the brewery’s water from the Johannesburg municipal supply. (3)

During the brewing process, cold water must first be boiled and then sent to the Brewhouse (4) to produce sweet wort (see Part 3). The brewpub’s kitchen (5) will also lend spent energy to the heating system, and pipes will run over hot surfaces and inside the chimney of the pizza oven. Heating water is typically very energy intensive, and utilising otherwise wasted energy will help create a more sustainable brewery. For cooling, pipes will run below the water of the stormwater pool (6) before the wort makes its way to the fermentation tanks, (7) and eventually to the bottling plant, (8) again running through the whole building. In this way, heat is pumped throughout the building, and not wasted. Additional modern sustainability measures are to be implemented in the design of the brewery – A pre-masher will mix the dry grist with water to produce a ready-mash, which is distributed through extra large (100mm diam.) pipes so that heat is not lost adding the grist to hot water. Modern agitator technology makes it possible to reduce the speed of agitation during brewing, reducing oxygen intake and stress on the mash, reducing energy requirements.